AVEVA Wonderware is a whole suite of industrial software solutions that are intended to improve industrial operations’ productivity, dependability, and efficiency. AVEVA Wonderware is a top option for several sectors due to the following important features:

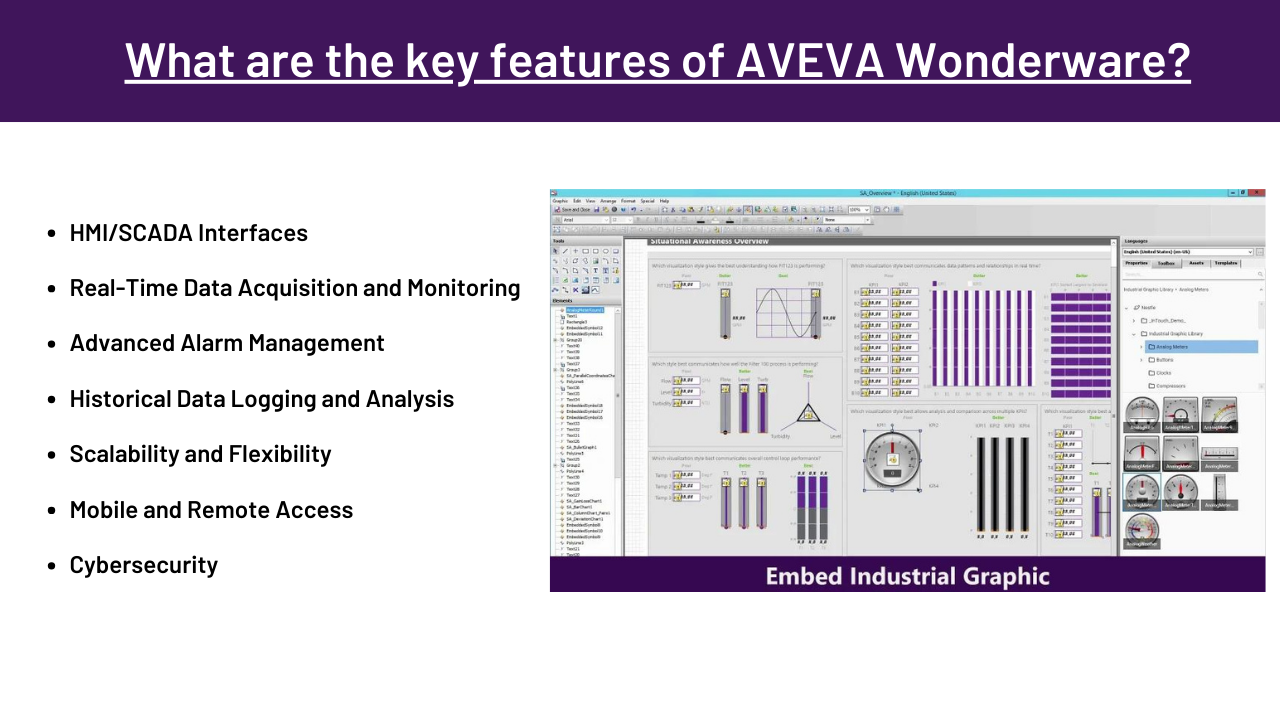

1. Intuitive HMI/SCADA Interfaces

Wonderware offers Supervisory manage and Data Acquisition (SCADA) and Human-Machine Interface (HMI) solutions that are easy to use, allowing operators to easily monitor and manage industrial operations.

Wonderware provides a powerful graphical design environment that makes it simple for customers to construct unique HMIs. You may arrange different controls and elements on the interface, such gauges, indicators, and buttons, by using the drag-and-drop feature. This method makes the design process more user-friendly and accessible, especially for those without a lot of programming experience.

2. Real-Time Data Acquisition and Monitoring

AVEVA Wonderware is a leader in real-time data gathering, providing technologies for industrial data collection, visualisation, and analysis. This feature guarantees that operators have instant access to vital process data, facilitating prompt decision-making and adaptable control.

Programmable Logic Controllers (PLCs), Remote Terminal Units (RTUs), sensors, and other field devices are just a few of the industrial sources that Wonderware may collect data from. This broad compatibility guarantees the collection and monitoring of data from all essential industrial system components.

3. Advanced Alarm Management

Strong alarm management systems provided by Wonderware assist operators in recognising problems and taking quick action. Prioritisation, customisable alerts, and thorough alarm records improve situational awareness and guarantee that important occurrences are handled effectively.

4. Historical Data Logging and Analysis

Strong data logging and historical data analysis facilities are included in the programme. To assist with ongoing development and operational optimisation, users may create reports, evaluate trends, and store enormous amounts of process data.

Wonderware allows for the thorough recording of process data, including all relevant variables such as temperatures, pressures, flow rates, and equipment status. This data may be stored in databases for long-term preservation, making earlier data readily available for analysis.

High-resolution data collection is supported by the software, which captures data often to provide precise and comprehensive history records. For the purpose of diagnosing intermittent faults and analysing quick changes in processes, this high-resolution data is essential.

5. Scalability and Flexibility

The scalable solutions from Wonderware may expand along with your business. Wonderware may be customised to meet your demands, regardless of the number of sites or facilities you oversee. This makes it appropriate for both small and large industrial organisations.

Thanks to Wonderware’s modular architecture, customers may customise the system to meet their unique needs by deploying only the components they require. Because of this architecture, businesses may start small and add new features to their systems gradually as their needs change, all without having to completely redesign the system.

Wonderware allows for vertical as well as horizontal scaling. Organisations may divide the burden by adding new nodes or instances thanks to horizontal scalability, while existing nodes can have their capacity increased by to vertical scalability.

6. Integration Capabilities

A large variety of industrial devices, protocols, and software systems are all easily integrated with Wonderware. By guaranteeing seamless connection between various elements of your industrial ecosystem, this interoperability improves overall effectiveness and data coherence.

7. Mobile and Remote Access

Operators can keep an eye on and manage operations from any location with the help of mobile and remote access technologies. This feature guarantees that vital information is always available, wherever you are, and facilitates flexible operations.

Mobile apps with control and real-time data access are available from AVEVA Wonderware. Operators may keep connected to their systems using their smartphones or tablets by downloading these apps, which are compatible with both iOS and Android platforms.

The responsive architecture of Wonderware’s HMI/SCADA interfaces guarantees that they work well across a range of screens and gadgets. Because of this architecture, operators may access the entire system’s capabilities without requiring a special app by using web browsers on their mobile devices.

8. Cybersecurity

Wonderware prioritises cybersecurity and provides tools to shield your information and systems from online threats and unauthorised access. Your activities are protected by encrypted communications, secure user authentication, and adherence to industry standards.

Check :- Website Development Kansas City Fast Online Company

9. Workflow Automation

By supporting workflow automation, the programme enables users to simplify repetitive operations and procedures. Automation minimises mistakes, boosts operational efficiency, and decreases manual involvement.

10. User-Friendly Development Environment

Wonderware offers an easy-to-use development environment for building unique programmes and user interfaces. The construction and deployment of HMI/SCADA applications are made easier by the drag-and-drop feature and a library of pre-designed objects and templates.

12. Multi-Language Support

The programme may be used by anyone worldwide because it supports several languages. International businesses that operate in many locations can especially benefit from this capability.

Given its extensive feature set aimed at improving industrial operations’ productivity, dependability, and efficiency, AVEVA Wonderware commands a premium price in the industrial software industry. Wonderware gives you the tools to optimise and simplify industrial processes, from simple HMI/SCADA interfaces and real-time data monitoring to sophisticated alarm management and predictive maintenance. It can respond to the various demands of global industries thanks to its scalability, integration capabilities, and cybersecurity emphasis.