Custom printing has become a cornerstone of modern fashion, marketing, and branding. Among the various techniques available, silk screen printing stands out as the most versatile and reliable method. Whether you’re printing t-shirts, posters, or promotional items, silk screen printing offers unmatched quality, durability, and vibrancy. At silk Screen Dallas we have explored this method to be the best for custom printing. In this article, we explore why silk screen printing is considered the best method for custom printing.

The Basics of Silk Screen Printing

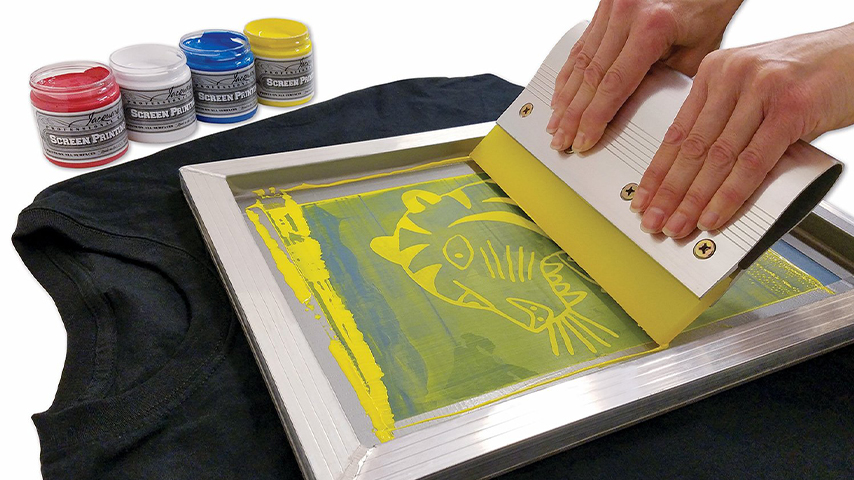

Silk screen printing, also known simply as screen printing, involves transferring ink onto a substrate (like fabric or paper) through a mesh screen. A stencil, or design, is applied to the screen, blocking the ink in certain areas and allowing it to pass through in others. Here’s a breakdown of the process:

1. Preparing the Design:

- The design is created digitally and then transferred onto a transparent film.

- The film is used to expose a light-sensitive emulsion on the screen, creating a stencil.

2. Setting Up the Screen:

- The screen, usually made of fine mesh fabric, is coated with the light-sensitive emulsion.

- The emulsion-coated screen is exposed to UV light through the transparent film, hardening the emulsion where the light hits and leaving the design area soft.

3. Printing:

- The screen is placed on the substrate, and ink is spread across the screen with a squeegee.

- The ink passes through the open areas of the stencil, transferring the design onto the substrate.

- Multiple screens are used for multi-color designs, with each screen representing one color.

4. Curing:

- The printed item is then cured, usually by passing it through a dryer, to set the ink.

Advantages of Silk Screen Printing

1. High Quality and Durability

One of the biggest advantages of silk screen printing is the superior quality and durability of the prints. The thick layer of ink applied during the process creates vibrant, long-lasting colors that withstand multiple washes and heavy use.

Key Benefits:

- Vibrant Colors: The ink used in silk screen printing is thicker than that used in other methods, resulting in more vibrant and opaque colors.

- Durability: The prints are resistant to fading and cracking, making them ideal for items that will be used and washed frequently, such as t-shirts and tote bags.

2. Versatility

You can use Silk screen printing on a wide variety of materials, including fabric, paper, wood, glass, and metal. This versatility makes it a go-to method for custom printing needs across different industries.

Key Applications:

- Apparel: T-shirts, hoodies, and other garments.

- Promotional Items: Bags, hats, and other merchandise.

- Art and Posters: High-quality art prints and posters.

- Industrial Uses: Labels, signs, and more.

3. Cost-Effectiveness for Large Orders

For large print runs, silk screen printing is incredibly cost-effective. The initial setup costs for creating screens and preparing the design. Are offset by the low per-unit cost of printing large quantities.

Key Considerations:

- Economies of Scale: The more items you print, the lower the cost per unit, making it ideal for bulk orders.

- Efficiency: Once set up, the process is fast, allowing for quick turnaround times on large orders.

4. Customization and Special Effects

Silk screen printing allows for a high degree of customization, including special effects such as metallic inks, glitter, and puff prints.

Key Features:

- Special Inks: Use of specialty inks like metallics, fluorescents, and glows-in-the-dark can create unique and eye-catching designs.

- Textural Effects: Techniques like puff printing or high-density printing add texture and dimension to the prints.

Environmental and Sustainability Considerations

Modern advancements in silk screen printing have made it more environmentally friendly. Water-based inks and eco-friendly emulsion options reduce the environmental impact of the printing process.

Key Improvements:

- Water-Based Inks: The environmental impact of these inks is lower than that of conventional plastisol inks.

- Eco-Friendly Materials: Screens, squeegees, and other materials are increasingly make from sustainable resources.

Limitations and Considerations

While silk screen printing offers numerous advantages. It also has some limitations that you should consider:

1. Initial Setup Cost:

- The initial cost of creating screens and preparing the design can be high, which might not be cost-effective for small orders.

2. Complexity with Multi-Color Designs:

- Each color in the design requires a separate screen, which can increase setup time and costs for complex, multi-color prints.

3. Not Ideal for Photographic Prints:

- Silk screen printing is not the best method for designs. It require fine detail or photographic quality, as it is better for bold, graphic designs.

Conclusion

Silk screen printing remains the gold standard for custom printing due to its superior quality, durability, and versatility. It is particularly advantageous for large orders and projects that require vibrant, long-lasting prints on a variety of materials. While there are some initial setup costs and limitations with highly detailed designs, the benefits far outweigh these drawbacks for most applications. Whether you’re looking to create custom apparel, promotional items, or high-quality art prints, silk screen printing offers a reliable and effective solution that ensures your designs stand out with exceptional clarity and color.